Have you ever wondered what truly goes into engine restoration and why cylinder head rebuilding is such a big deal? Perhaps you’ve heard terms like “motorcycle crankshaft grinding” or “crankshaft reconditioning” thrown around, but you’re not entirely sure how these services fit together. If so, you’ve come to the right place. Here, we’ll explore the fascinating world of cylinder head rebuilding and crankshaft machining cost considerations, helping you navigate some of the most common questions and concerns along the way.

In this blog post, we’ll look at the importance of the engine cylinder head, why it’s critical to keep it in top shape, and how to pick the right experts to rebuild or repair your engine. We’ll also dive into how to rebuild an engine step by step, uncover the significance of crankshaft grinding services, and warm you up to essential cost factors like crankshaft grinding prices and cylinder head rebuilding costs. By the end, you’ll have a firm grasp on what to look for in a workshop, how to balance speed and quality, and when a complete rebuild might be more economical than a partial fix.

Whether you’re a passionate motorcyclist or someone keen to learn about your everyday vehicle’s engine, these tips will give you the insights you need. Let’s get stuck into the details, so you can decide with confidence when you spot that suspicious puff of smoke or hear that odd engine rattle. After all, looking after your engine now can save you a lot of headaches—and hefty repair bills—later on.

Why Cylinder Head Rebuilding Matters

Cylinder head rebuilding can sound like a complicated affair, but it’s actually a crucial step in extending your engine’s life. Whether you’re dealing with a car or a motorcycle, a healthy cylinder head ensures strong compression, proper heat distribution, and smooth engine performance. If anything goes wrong in this area, you could find yourself grappling with frequent breakdowns and costly repairs, or even a total engine failure. Avoiding these problems is why many people turn to crankshaft reconditioning or crankshaft nitriding service as part of a thorough engine overhaul.

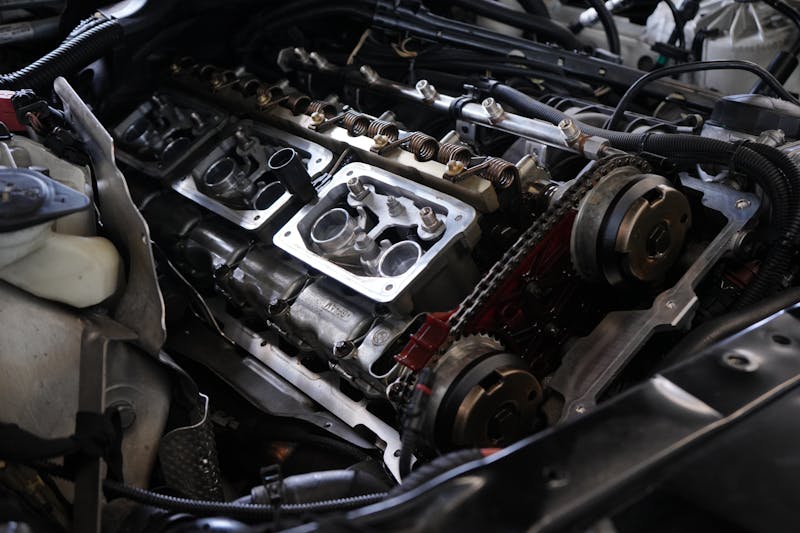

Understanding the Engine Cylinder Head

The engine cylinder head is a key component that sits on top of the engine block. It channels airflow in and out of the cylinders, while also housing vital parts like the valves and spark plugs. In simple terms, it’s the centre of combustion. Without a well-maintained cylinder head, your engine’s entire function can come undone. Issues like cracked heads, warped surfaces, or worn-out valves could result in poor fuel efficiency and constant overheating. By comparison, a freshly rebuilt or repaired cylinder head motor will help maintain strong performance and stable power output.

What Is a Cylinder Head Motor, and Why Is It Important?

A cylinder head motor is simply another way of referring to an engine’s top section where the fuel-air mixture ignites. This component is important because it acts as a sealed chamber for combustion, controlling how efficiently fuel is converted into power. When the cylinder head isn’t working properly—due to cracks, leaks, or warping—combustion can’t occur at its peak capacity. You might notice a drop in horsepower, increased fuel consumption, or rough idling. Rebuilding a damaged head can restore lost performance and prevent further mechanical troubles down the line.

Common Rebuilding Needs Beyond the Cylinder Head

While the cylinder head is often the prime suspect in many engine troubles, other parts need attention too. You might consider motorcycle crankshaft grinding to smooth out worn journals, or crankshaft reconditioning to restore original dimensions and balance. Crankshaft nitriding service is another option, adding a hardened layer that improves longevity and resistance to fatigue. Combining these complementary services ensures you get a thorough engine refresh rather than merely patching up one area. It’s like getting a new lease on life for your engine—improving reliability, performance, and overall cost-effectiveness in the long run.

Ensuring Comprehensive Rebuilding Scope

When you’re deciding on a cylinder head rebuilding service, make sure they’re prepared to address the entire engine, not just the top half. An engine is composed of interconnected systems, and focusing on only one piece may lead to lingering issues or future failures. The best workshops consider everything from valve seats to crankshaft grinding process steps, ensuring a balanced and integrated rebuild.

Key Steps: How to Rebuild an Engine

“How to rebuild an engine” is a massive topic in its own right. But the main steps often include disassembly, cleaning, inspection, machining or repair of worn components, and careful reassembly with new gaskets and seals. For instance, you might discover that your crankshaft journals have scratches or scoring. In that scenario, a machine shop might recommend crankshaft regrinding cost estimates, so that any irregularities are removed before the final build. By making sure your workshop covers these bases, you can confirm the finished product is reliable, powerful, and properly balanced.

The Crankshaft Grinding Process and Its Significance

The crankshaft grinding process is not just about ironing out scuffs. When you grind a crankshaft, you’re removing small layers of metal to reshape it to the manufacturer’s recommended dimensions. This can correct warping or uneven wear that can cause vibrations or reduced performance. A well-ground crankshaft is vital for maintaining engine timing and balance, so it’s something you shouldn’t skimp on. After all, the crankshaft is the main rotating component; if it’s not precise, the entire engine might suffer.

Is an Engine Rebuild in a Can Effective?

Have you ever seen popular products advertised as an “engine rebuild in a can?” While these additives might temporarily quiet some top-end engine issues or reduce oil consumption, they won’t solve deep mechanical faults. If you’re experiencing significant engine problems—like constant overheating or severe knocking—additives can’t replace the need for a proper workshop diagnosis. Think of “engine rebuild in a can” as the quick fix that may buy you time, but not a permanent solution. In contrast, a comprehensive rebuild will address the root causes, ensuring a longer-lasting and more dependable engine.

Cylinder Head Rebuilding Services

Checking Workshop Expertise and Equipment

A workshop is only as good as the people and the equipment behind it. Look for industry experts who have a wealth of knowledge in cylinder head rebuilding and crankshaft grinding services. Sheer passion doesn’t guarantee success—modern equipment, proven techniques, and a well-trained team do.

Evaluating Crankshaft Machining Cost, Crankshaft Grinding Services, and Prices

Before you go ahead with any service, gather quotes for your crankshaft machining cost and crankshaft grinding prices. A reputable shop should provide a detailed breakdown, including potential extra fees for parts or additional labour. Don’t be afraid to ask why certain steps are suggested. If they’re recommending nitriding to enhance your crankshaft’s surface hardness, ask about the long-term benefits. This insight can help you differentiate between a genuine expert and a workshop merely trying to upsell.

Crankshaft Rebuilders Brisbane: Choosing a Trusted Provider

If you’re in Australia, you may come across numerous ads for crankshaft rebuilders Brisbane wide. How do you choose a provider you can trust? Start by checking their reputation, both online and through word-of-mouth. Look for reviews from past customers who’ve had their engines rebuilt or cylinder heads restored. Another handy tip is to visit the workshop if possible. Cleanliness, organised work areas, and modern equipment often hint at a professional operation that values quality.

What Makes a Quality Crankshaft Reconditioning Service?

A quality crankshaft reconditioning service involves more than just swapping worn bearings. The workshop should conduct initial inspections like crack detection, dimensional checks, and hardness testing. If your crankshaft is out of tolerance, they might suggest regrinding or building up the journals using specialised welding or plating. Once restored, some shops apply a nitriding service to make the material stronger and more wear-resistant. When these steps are carried out meticulously, you’ll end up with a crankshaft that runs like new and will keep your engine cylinder head performing at its peak.

Comparing Costs and Pricing

Money matters, especially when it comes to major repairs. But watching your wallet doesn’t mean you should compromise on quality. It’s helpful to consider both short-term and long-term expenses. Paying a bit more upfront for reputable crankshaft grinding services can work out cheaper than repeated breakdowns in the future.

Crankshaft Grinding Cost, Regrinding Cost, and Overall Budget Considerations

Crankshaft grinding cost and regrinding cost can vary based on labour rates, the extent of damage, and the type of engine. A motorcycle crankshaft grinding job might be less expensive than dealing with a large diesel engine from a commercial vehicle. It’s worth getting multiple quotes before making a final decision. Just remember that the cheapest option isn’t always the right call. If a shop’s quote is suspiciously low, confirm they’re not skipping important quality checks or using outdated equipment.

How Much Does Cylinder Head Rebuilding Typically Cost?

The question “How much does cylinder head rebuilding typically cost?” doesn’t have one straightforward answer. It depends on the make and model of your engine, the extent of the damage, and the quality of parts needed. For instance, a simple valve job might be relatively cheap, whereas a cylinder head with cracks or major warping will drive the cost up. Some shops offer a bundled “head and crank rebuild” package, which can be a better deal than addressing each part separately. Weigh your options and ask about warranties. Workshops that stand by their work might offer extended guarantees, signalling confidence in their services.

Weighing Up Crankshaft Grinding Prices vs Cylinder Head Rebuild Expenses

If both your cylinder head and crankshaft need attention, it’s easy to feel torn about where to start. The best approach is to get an overall assessment from experts. If the damage is significant in both areas, a complete rebuild might offer better value than doing them one at a time. This approach often saves labour costs and downtime, especially if the engine has to be removed from the vehicle or bike more than once. Plus, when you tackle both tasks together, you can ensure all components operate seamlessly, from the cylinder head motor to the newly refaced crankshaft journals.

Conclusion

Summing up, choosing the right cylinder head rebuilding service doesn’t have to feel overwhelming. By understanding the role of the engine cylinder head, the importance of complementary repairs like crankshaft grinding, and the value of exploring reputable crankshaft rebuilders Brisbane wide, you’re well on your way to making a solid decision. We’ve also covered the significance of comparing prices, balancing quality with speed, and ensuring you ask about guarantees and post-rebuild support.