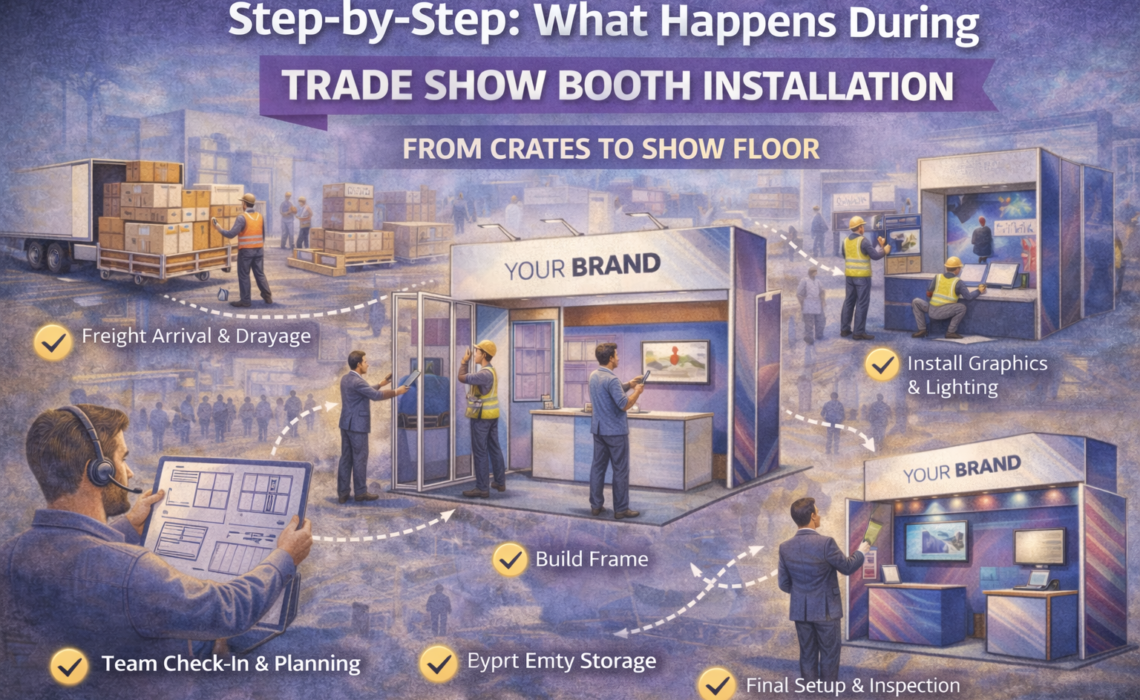

To attendees walking onto a trade show floor, everything looks effortless. Booths are lit beautifully. Graphics are perfectly aligned. Screens are playing polished videos. Staff members are smiling and ready for conversations.

What most people never see is what happened hours or sometimes days, before the doors opened.

Trade show booth installation is not just “setting up a display.” It’s a carefully timed operation involving freight teams, union labor, supervisors, electricians, floor managers, and exhibit specialists-all working within strict venue rules and tight deadlines.

When it’s done well, it looks easy.

When it’s not, it leads to stress, delays, extra costs, and unfinished booths minutes before opening.

Here’s what really happens behind the scenes.

Step 1: Freight Arrives at the Convention Center

Before anything can be built, the booth has to physically arrive.

Freight usually ships either to:

- An advance warehouse days before the show, or

- Directly to the convention center during the official move-in window

But the truck doesn’t just pull up to your booth space.

First, it checks in at a marshaling yard or loading dock where paperwork is reviewed and trucks wait their assigned unloading time. Bills of Lading, shipping labels, and crate identification are verified carefully.

If paperwork is incorrect or labels are unclear, delivery to the show floor can be delayed.

This is where good logistics planning makes a huge difference.

Step 2: Drayage – Moving Freight to Your Booth

Once cleared, forklifts transport the crates from the dock to your booth location. This process is called drayage (or material handling).

In massive convention halls, forklifts may travel long distances through aisles filled with other exhibitors building at the same time. It’s organized chaos-dozens of teams working simultaneously under strict schedules.

Crates are placed inside your booth space, and for many exhibitors, this is the first time they see their materials on-site.

Step 3: The Installation Team Plans the Build

Before anyone opens a crate, the installation supervisor gathers the crew.

They review:

- Booth layout drawings

- Assembly sequence

- Electrical and lighting plans

- Graphic placement

- Individual labor assignments

This short planning session prevents confusion and saves hours later. A clear sequence ensures the build moves efficiently from start to finish.

Step 4: Crates Are Opened and Components Organized

Crates are opened methodically-not randomly.

Each component is removed and placed in a logical order based on the assembly plan. Trade show booths often include:

- Structural frames and support beams

- Wall panels and backdrops

- Fabric graphics and prints

- Counters and shelving

- Lighting fixtures and wiring

- Screens and demo equipment

Organizing everything first avoids costly mistakes later in the build.

Step 5: Building the Booth’s Structure

Installation begins with the booth’s skeleton.

Frames, beams, back walls, and hanging structures are assembled first. This defines the physical footprint of the booth.

Precision is critical here. If the frame is even slightly misaligned, graphics won’t fit properly and panels may not sit flush. Experienced installers constantly measure and adjust to ensure structural accuracy.

This stage sets the foundation for everything that follows.

Step 6: Electrical and Lighting Installation

Once the structure is secure, electricians step in.

They handle:

- Power connections from floor ports

- Installation of spotlights and overhead lighting

- Wiring for monitors and devices

Lighting is tested early. Good illumination isn’t just functional-it dramatically affects how your brand looks on the show floor.

A booth can look average or exceptional depending on lighting alone.

Step 7: Installing Graphics and Branding

Now the transformation begins.

Graphics are carefully mounted, stretched, aligned, and secured. This includes:

- Large wall graphics

- Fabric panels

- Branding headers

- Backlit displays

Installers smooth out wrinkles, align edges perfectly, and ensure branding is centered and sharp.

At this point, the booth starts to feel like a branded environment instead of a construction zone.

Step 8: Counters, Furniture, and Displays

Next come the functional elements:

- Reception counters

- Demo stations

- Product displays

- Shelving units

- Seating areas

Everything is positioned according to the approved floor plan to support natural visitor flow and easy staff interaction.

Good placement makes the space feel inviting. Poor placement creates congestion.

Step 9: Technology Setup and Testing

Screens are mounted. Tablets are powered on. Video loops are tested. Wi-Fi connections are verified.

This is when:

- Presentations are checked

- Charging stations are confirmed

- Demo equipment is powered up

Any technical issue discovered now can be resolved before showtime, when it matters most.

Step 10: Empty Crate Labeling and Removal

After installation, the empty crates must disappear.

Each crate is labeled carefully with return information and moved to a designated storage area. This step is more important than it sounds.

Those crates will be needed during dismantle. If labeling is wrong, chaos can follow after the show.

Experienced teams treat this step seriously.

Step 11: Cleaning and Final Touches

Construction dust is removed. Floors are vacuumed. Graphics are wiped down. Lighting angles are adjusted for optimal effect.

What was a busy work zone hours earlier now looks polished and professional.

Step 12: Final Walkthrough and Quality Check

Before declaring the booth complete, the supervisor performs a detailed inspection:

- Are all graphics aligned properly?

- Is lighting functioning correctly?

- Are structural elements stable and secure?

- Is everything installed according to plan?

Only after this walkthrough is the booth officially considered show-ready.

Step 13: Handover to the Exhibitor

When exhibitors arrive, they see a finished space.

They can:

- Place brochures

- Arrange giveaways

- Power up devices

- Brief their team

They don’t see the forklifts, the paperwork checks, the alignment adjustments, or the coordinated timing that made it possible.

They simply step into a ready environment.

Why Installation Requires Real Expertise?

Booth installation happens under:

- Strict time limits

- Crowded, high-pressure environments

- Union labor regulations

- Logistical coordination across multiple teams

One delayed truck, one missing part, or one installation error can impact the entire timeline.

Professional installation teams understand this environment. They follow a disciplined sequence that ensures the booth is completed efficiently and safely.

What Many Exhibitors Don’t Realize?

From the outside, installation looks like “putting pieces together.”

In reality, it’s a coordinated operation involving:

- Freight management

- Labor scheduling

- Technical setup

- Quality control

- Real-time problem-solving

That invisible work is what creates a smooth trade show experience.

Final Thoughts

Trade show booth installation is the moment months of planning become physical reality. It’s a structured, step-by-step process that transforms crates and components into a fully branded space ready to attract visitors.

When handled professionally, it feels seamless. When underestimated, it becomes stressful and expensive.

Understanding what happens behind the scenes helps exhibitors appreciate the precision required and the importance of having experienced teams managing every step from freight arrival to final inspection.

Because when the doors open, everything should feel effortless.